Precision Lock Cylinder Manufacturing

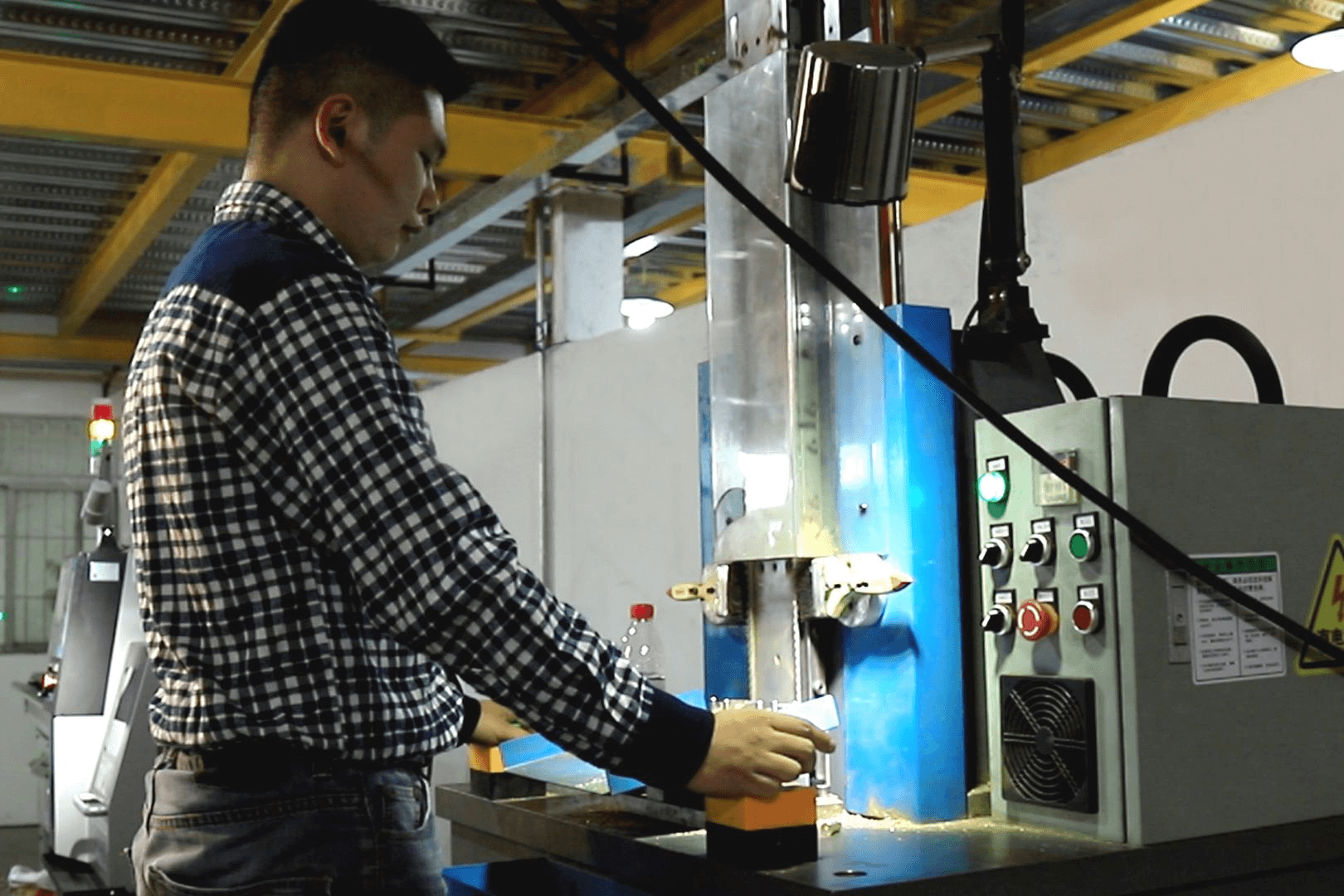

EOS Secure precision-lock-cylinder manufacturing facility is equipped with top-of-the-line CNC machines operated by highly-skilled engineers. This enables us to produce high-precision top-end lock cylinders with excellent efficiency and less tolerance.

Want to start a project with us? Contact us

How Precision Lock Cylinders Are Manufacturered

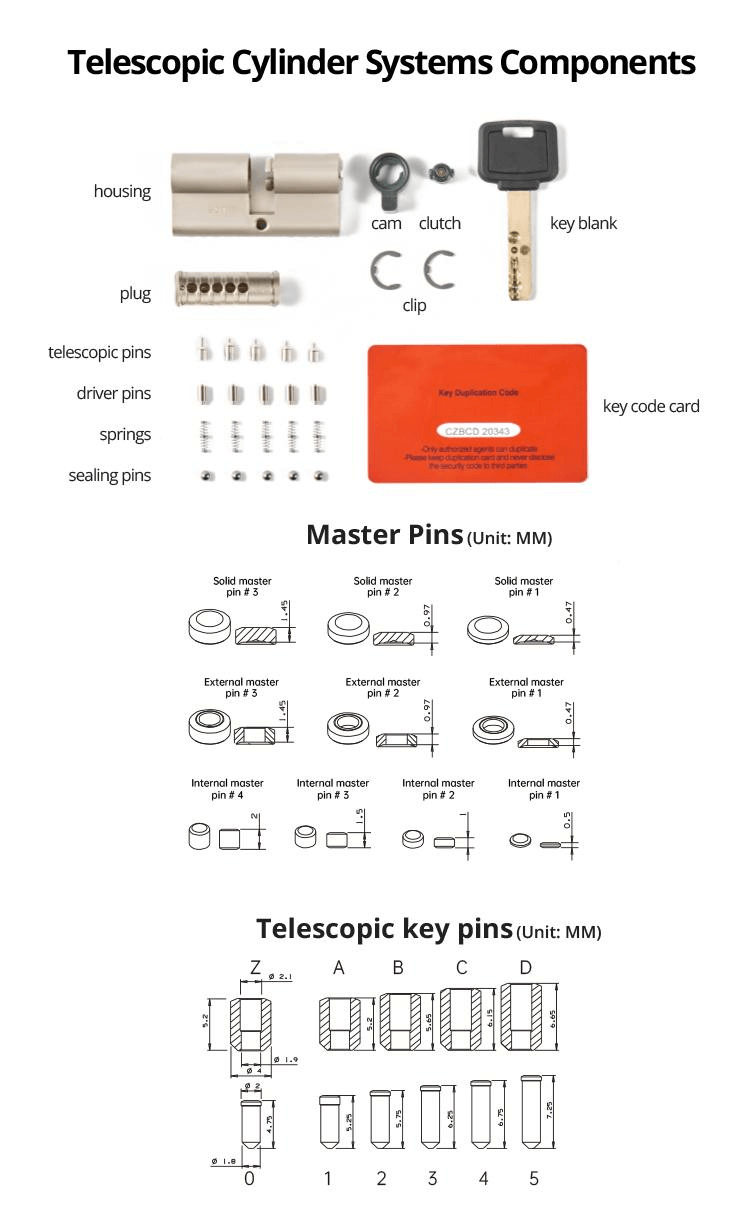

Our manufacturer is based in the famous hardware base region of Zhongshan, China, and manufactures more than 400,000 lock cylinders per month. Based on the modern plant with CNC machines, an experienced know-how team, and strict quality control methods, our lock cylinder production is intended for the premium end of the lock industry. A lock cylinder is made up of plug/roter, housing/stator, keys, pins, and other parts. The manufacturing of lock cylinders comprises several stages, including lathing, drilling, broaching, milling, turning, bitting, cutting, and punching processes on related parts.

How to Produce Lock Cylinders Step by Step

Master key system cylinders and Security cylinders manufacturer

01

Raw Materials for Making Lock Cylinders

Raw materials that we primarily use in the manufacture of lock cylinders are brass and silver nickel materials. The brass material that we use is H59 grade brass according to GB/T 4423-2007 standard, which includes 56%-58% of Cu. The material keeps significantly less tolerance after machining and of outstanding performance of anti-corrosion and mechanical properties.

Silver nickel material is typically used in high-end keys, including 9%-12.5% of Ni and over 65% of Cu. Besides all the advantages of brass material, silver nickel also increases the strength of the key because of the Ni element.

02

Lathing, Drilling, Milling and Broaching for Lock Plugs

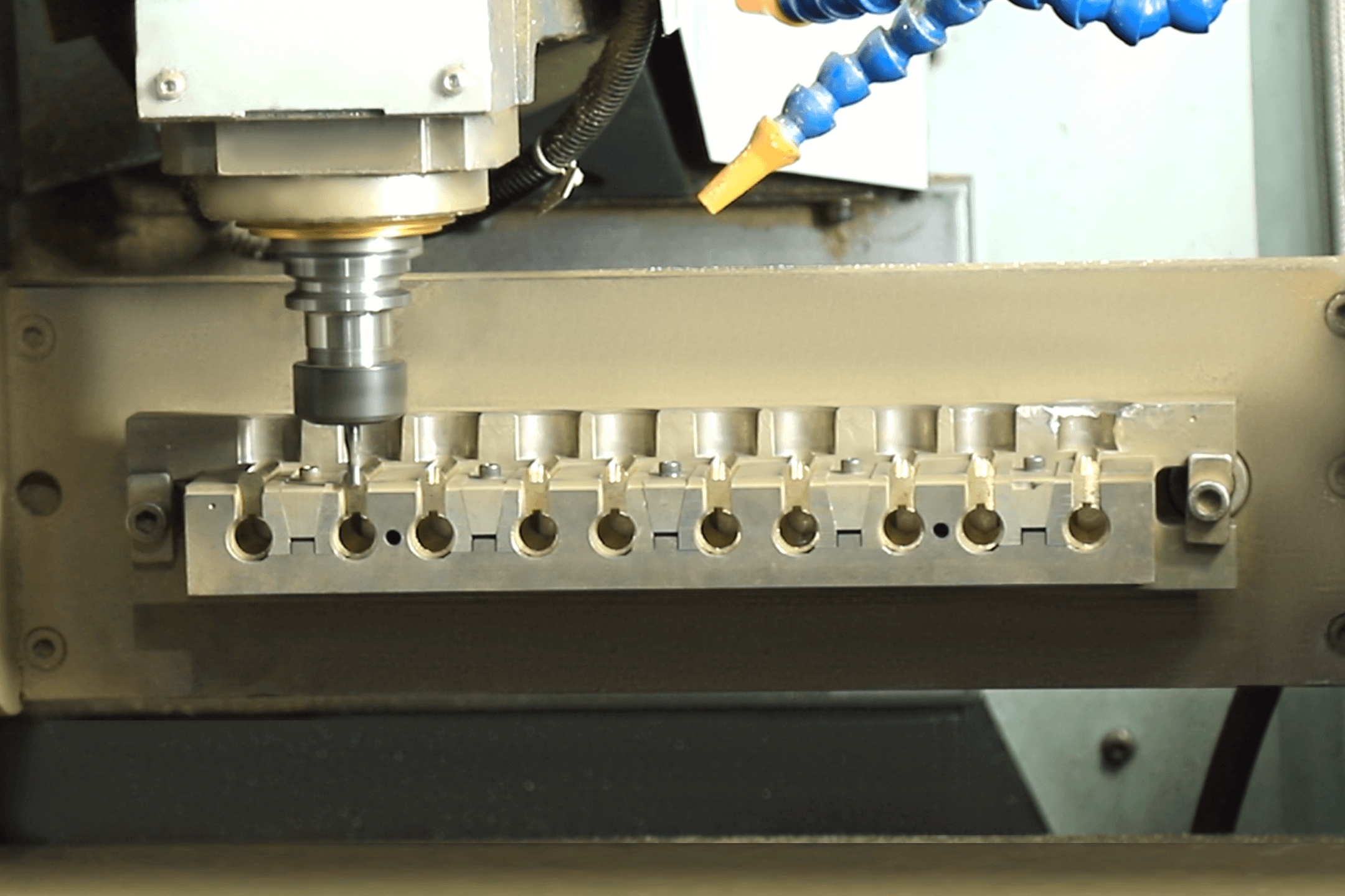

The lock plugs are the core part of the lock cylinder. Precision lathing, drilling necessary all kinds of pins holes, milling, and broaching key profiles are the processes we implement.

Drilling of pins holes is critical. Some high-end cylinders are made up of not only active pins, but also side pins, snake pins, passive pins, angle pins, and so on, so the precision of the relationship of these pins becomes the key factor when producing the lock cylinder.

Broaching is an essential phase of making key profiles—the precision between key profiles and pins determines the quality and precision of the lock cylinders.

Some functions/features are able to be optionally customized:

• anti-drilling pins • floating pins

• anti-snapping cuts • customized pins holes size and distance

• construction key pin holes

• side pins/back pins/lateral pins

• snake pins

• restricted key way/ask for a new key way

03

Cutting, Lathing, Drilling, Milling and Polishing for Lock Housings

The machining precision of housings is crucial, for example, the precision of drilling of pin holes and the smoothness of the plug holes.

EOS Secure applies the CNC 4-Axis Machining Centers to finish some drilling, milling, and cutting tasks to ensure the machining tolerance can be less than 0.03mm.

EOS Secure also uses different kinds of transfer machines to achieve the high-productivity. The advantage is high precision and high productivity.

Some functions/features are able to be optionally customized:

• anti-drilling pins

• anti-snapping cuts

• anti-breaking bar

• side pins/back pins/lateral pins groove

• snake pins groove

• customized modular system

• customized pins holes size and distance

• customized length

• customized label

04

Punching, Broaching, Milling, Bitting, Cutting, Labeling for Keys

A key is a bridge linking all the necessary parts inside the cylinders. The incredible precision reflects on key profiles tolerance, key cutting, and bitting tolerance.

EOS Secure applies CNC Broaching machines for key profile broaching. Our experienced workers save lots of time and ensure the precision of the broaching every time by just setting the machines up. This is a good choice for locksmiths who require the precision parts such as key blanks and pins.

Thanks to the automatic key cutting/bitting machines for normal teeth keys and dimple keys, EOS controls the key cutting and bitting tolerance within 0.05mm. We laser the codes together with the corresponding keys.

Some functions/features are able to be optionally customized:

• metal key bow

• plastic key bow

• brass or silver nickel (cupronickel) material

• side pins/back pins/passive pins/lateral pins

• snake pins

• floating pins/other floating elements

• construction keys

• customized modular system

• customized pins holes size and distance

• customized label

• restricted key way/ask for a new key way

05

Surface Treatment

Surface treatments are performed on the appearance of lock cylinder parts when finishing machining.

Before sending the parts to the next stage, we have to polish the surface of the lock cylinders parts, such as plugs, housings, thumbturns, and so on. We have two kinds of polishing techniques: manual polishing and machinery polishing. The dimension of the housings can be produced based on Din standard: 33*17*10mm.

After polishing, we will send all the after-polishing parts to electroplating, powder coating, or PVD treatment. Depending on different markets, we usually produce satin nickel (SN), satin brass (SB), black (BLK), satin chrome or polished chrome (SC or PC), and PVD gold. Customization on the surface treatment is always available. EOS Secure implements strict quality control of the inspection on surface treatment. Our experienced staff will check every piece during IQC (incoming material) stage. If our customers have requirements regarding the salt-spray test result, we can customize it for them.

Some functions/features are able to be optionally customized:

• remove sharp edge from the certain parts

• maintain the housing dimension at Din standard

• different electroplating finishes

• different powder coating finishes

• different PVD finishes

06

Producing Plugs, Housings, Pins, Key Blanks for Supplying to Locksmiths as Accessories

One of EOS Secure’s import customer bases is locksmiths. Most manufacturers can produce lock cylinders, but not all of them are willing to deliver only plugs, housings, pins, key blanks, and parts to locksmith customers because this requires very high precision quality control on each piece.

Thanks to the strict quality control know-how team and professional inspection machines, EOS Secure has become very experienced in serving locksmiths customers by offering all the accessories needed.

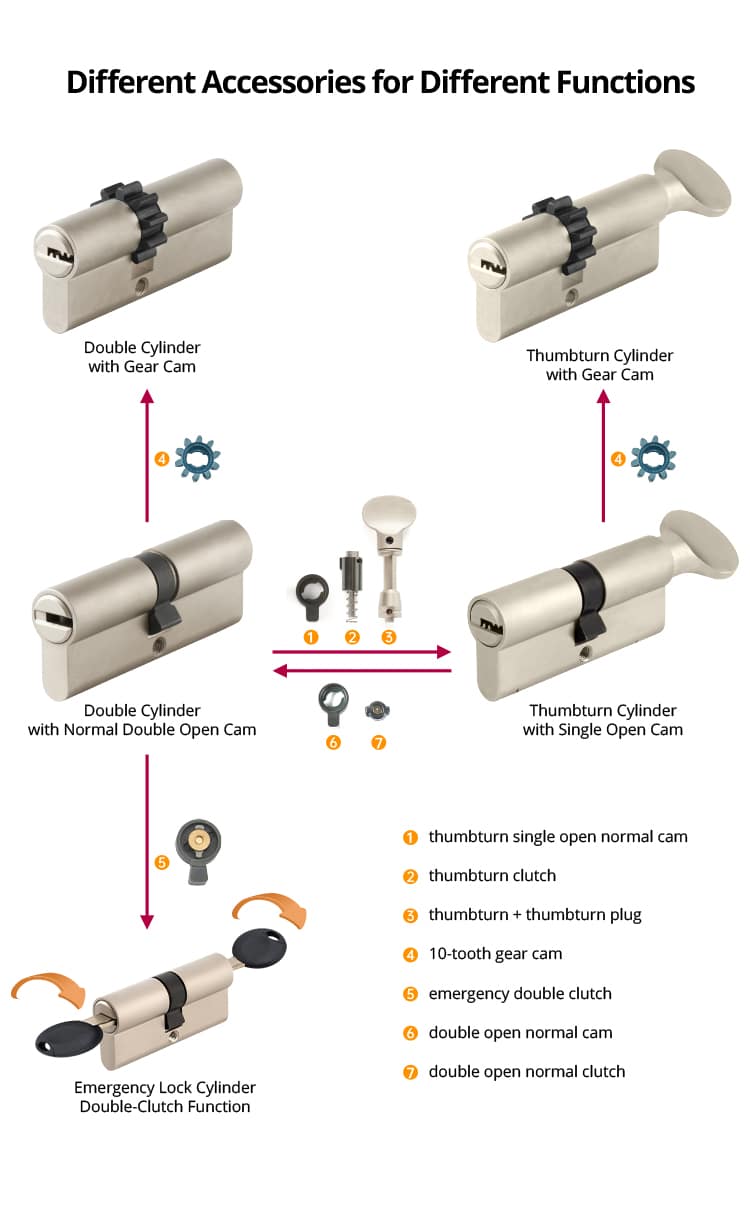

The accessories locksmiths may require:

• pins (top pins, bottom pins, master pins, sealed pins)

• circlips, springs

• cams (normal R15 cam, R13 cam, gear cam and so on)

• couplings (single open, double open and emergency clutch)

• thumbturns

• key blanks

• housings (single or double in different lengths)

• plugs (different lengths)

07

Assembling

EOS Secure assembling line is where we assemble all the parts as complete lock cylinders, implement finished products inspections and pack the goods.

EOS Secure issues the detailed assembly instructions for each lock cylinder to ensure the workers assemble the cylinders in the right way.

For assembling master key systems, our engineer will print the code list regarding this project, and our workers will follow the code list to assemble the master key system. Different workers will assemble corresponding codes to avoid mistakes.

Finally, our QC team will check the functions of all the cylinders one by one. As for the master key system, our QC team will use the master key of each group to open all the cylinders to test the accessibility. At the same time, our QC team will also check the mutual opening problems by using each KD key (basic level) to open all the cylinders one by one. Ensure the master key system cylinders in your project are the most assured hardware.

How to Produce Lock Cylinders Step by Step

Master key system cylinders and Security cylinders manufacturer

01

Raw Materials for Making Lock Cylinders

Raw materials that we primarily use in the manufacture of lock cylinders are brass and silver nickel materials. The brass material that we use is H59 grade brass according to GB/T 4423-2007 standard, which includes 56%-58% of Cu. The material keeps significantly less tolerance after machining and of outstanding performance of anti-corrosion and mechanical properties.

Silver nickel material is typically used in high-end keys, including 9%-12.5% of Ni and over 65% of Cu. Besides all the advantages of brass material, silver nickel also increases the strength of the key because of the Ni element.

02

Lathing, Drilling, Milling and Broaching for Lock Plugs

The lock plugs are the core part of the lock cylinder. Precision lathing, drilling necessary all kinds of pins holes, milling, and broaching key profiles are the processes we implement.

Drilling of pins holes is critical. Some high-end cylinders are made up of not only active pins, but also side pins, snake pins, passive pins, angle pins, and so on, so the precision of the relationship of these pins becomes the key factor when producing the lock cylinder.

Broaching is an essential phase of making key profiles—the precision between key profiles and pins determines the quality and precision of the lock cylinders.

Some functions/features are able to be optionally customized:

• anti-drilling pins • floating pins

• anti-snapping cuts • customized pins holes size and distance

• construction key pin holes

• side pins/back pins/lateral pins

• snake pins

• restricted key way/ask for a new key way

03

Cutting, Lathing, Drilling, Milling and Polishing for Lock Housings

The machining precision of housings is crucial, for example, the precision of drilling of pin holes and the smoothness of the plug holes.

EOS Secure applies the CNC 4-Axis Machining Centers to finish some drilling, milling, and cutting tasks to ensure the machining tolerance can be less than 0.03mm.

EOS Secure also uses different kinds of transfer machines to achieve the high-productivity. The advantage is high precision and high productivity.

Some functions/features are able to be optionally customized:

• anti-drilling pins

• anti-snapping cuts

• anti-breaking bar

• side pins/back pins/lateral pins groove

• snake pins groove

• customized modular system

• customized pins holes size and distance

• customized length

• customized label

04

Punching, Broaching, Milling, Bitting, Cutting, Labeling for Keys

A key is a bridge linking all the necessary parts inside the cylinders. The incredible precision reflects on key profiles tolerance, key cutting, and bitting tolerance.

EOS Secure applies CNC Broaching machines for key profile broaching. Our experienced workers save lots of time and ensure the precision of the broaching every time by just setting the machines up. This is a good choice for locksmiths who require the precision parts such as key blanks and pins.

Thanks to the automatic key cutting/bitting machines for normal teeth keys and dimple keys, EOS controls the key cutting and bitting tolerance within 0.05mm. We laser the codes together with the corresponding keys.

Some functions/features are able to be optionally customized:

• metal key bow

• plastic key bow

• brass or silver nickel (cupronickel) material

• side pins/back pins/passive pins/lateral pins

• snake pins

• floating pins/other floating elements

• construction keys

• customized modular system

• customized pins holes size and distance

• customized label

• restricted key way/ask for a new key way

05

Surface Treatment

Surface treatments are performed on the appearance of lock cylinder parts when finishing machining.

Before sending the parts to the next stage, we have to polish the surface of the lock cylinders parts, such as plugs, housings, thumbturns, and so on. We have two kinds of polishing techniques: manual polishing and machinery polishing. The dimension of the housings can be produced based on Din standard: 33*17*10mm.

After polishing, we will send all the after-polishing parts to electroplating, powder coating, or PVD treatment. Depending on different markets, we usually produce satin nickel (SN), satin brass (SB), black (BLK), satin chrome or polished chrome (SC or PC), and PVD gold. Customization on the surface treatment is always available. EOS Secure implements strict quality control of the inspection on surface treatment. Our experienced staff will check every piece during IQC (incoming material) stage. If our customers have requirements regarding the salt-spray test result, we can customize it for them.

Some functions/features are able to be optionally customized:

• remove sharp edge from the certain parts

• maintain the housing dimension at Din standard

• different electroplating finishes

• different powder coating finishes

• different PVD finishes

06

Producing Plugs, Housings, Pins, Key Blanks for Supplying to Locksmiths as Accessories

One of EOS Secure’s import customer bases is locksmiths. Most manufacturers can produce lock cylinders, but not all of them are willing to deliver only plugs, housings, pins, key blanks, and parts to locksmith customers because this requires very high precision quality control on each piece.

Thanks to the strict quality control know-how team and professional inspection machines, EOS Secure has become very experienced in serving locksmiths customers by offering all the accessories needed.

The accessories locksmiths may require:

• pins (top pins, bottom pins, master pins, sealed pins)

• circlips, springs

• cams (normal R15 cam, R13 cam, gear cam and so on)

• couplings (single open, double open and emergency clutch)

• thumbturns

• key blanks

• housings (single or double in different lengths)

• plugs (different lengths)

07

Assembling

EOS Secure assembling line is where we assemble all the parts as complete lock cylinders, implement finished products inspections and pack the goods.

EOS Secure issues the detailed assembly instructions for each lock cylinder to ensure the workers assemble the cylinders in the right way.

For assembling master key systems, our engineer will print the code list regarding this project, and our workers will follow the code list to assemble the master key system. Different workers will assemble corresponding codes to avoid mistakes.

Finally, our QC team will check the functions of all the cylinders one by one. As for the master key system, our QC team will use the master key of each group to open all the cylinders to test the accessibility. At the same time, our QC team will also check the mutual opening problems by using each KD key (basic level) to open all the cylinders one by one. Ensure the master key system cylinders in your project are the most assured hardware.

![MVI_8801[00_00_49][20220416-170914] lock cylinder machines](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_880100_00_4920220416-170914.png)

![MVI_3550[20220416-171823] 拷贝 lock cylinder punching key machine](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_355020220416-171823-%E6%8B%B7%E8%B4%9D.png)

![MVI_8767[00_00_06][20220413-084304](1) lock cylinder key cutting](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_876700_00_0620220413-0843041.png)

![MVI_3489[00_00_02][20220416-173037] lock cylinder quality](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_348900_00_0220220416-173037.png)

![MVI_8830[00_01_33][20220416-173223] 拷贝 lock cylinder surface treatment](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_883000_01_3320220416-173223-%E6%8B%B7%E8%B4%9D.png)

![中山市傲斯五金有限公司无配音验厂视频[00_01_33][20220418-171216] - 副本 lock cylinder assembling line](https://www.eos-secure.com/wp-content/uploads/2022/04/%E4%B8%AD%E5%B1%B1%E5%B8%82%E5%82%B2%E6%96%AF%E4%BA%94%E9%87%91%E6%9C%89%E9%99%90%E5%85%AC%E5%8F%B8%E6%97%A0%E9%85%8D%E9%9F%B3%E9%AA%8C%E5%8E%82%E8%A7%86%E9%A2%9100_01_3320220418-171216-%E5%89%AF%E6%9C%AC.png)

![中山市傲斯五金有限公司无配音验厂视频[00_01_46][20220418-171324] - 副本 precision lock cylinder assembling](https://www.eos-secure.com/wp-content/uploads/2022/04/%E4%B8%AD%E5%B1%B1%E5%B8%82%E5%82%B2%E6%96%AF%E4%BA%94%E9%87%91%E6%9C%89%E9%99%90%E5%85%AC%E5%8F%B8%E6%97%A0%E9%85%8D%E9%9F%B3%E9%AA%8C%E5%8E%82%E8%A7%86%E9%A2%9100_01_4620220418-171324-%E5%89%AF%E6%9C%AC.png)