Quality starts with the details

EOS is professional in manufacturing precision lock cylinders, which is why we have a department specializing in quality control to guarantee the quality of the products we provide.

Want to start a project with us? Contact us

![MVI_8825[20220510-175316] eos lock cylinders quality control](https://www.eos-secure.com/wp-content/uploads/2022/05/MVI_882520220510-175316.png.webp)

We Are Committed To Strict Quality Control

EOS secure is committed to quality management across all the aspects of production. Our QC team mainly implements First Article Inspection, Inprocess Quality Control Inspection, and Finished Products Inspection. With high-precision measuring tools, gauges, and other inspection machines, our QC team sets up the record system to make the whole QC system follow the ISO 9001 requirement. A lock cylinder is combined with many accessories, including plugs, housings, pins, keys, etc. The precision of the cylinder is the most critical element we always pursue. A strict quality control system helps EOS improve the product quality and awareness of high-end products.

How EOS Controls The Quality

Master key system cylinders and Security cylinders manufacturer

01

First Article Inspection

EOS invested in over 50 sets of CNC machines, which means our engineers only need to adjust the program in the computer, then finish the adjustment on the machines when producing different parts. After adjustment to the machines, our engineers and QC team will check the sizes and precisions of the first articles with clear work instructions and drawings. If the first articles fail to pass the inspection, our engineers re-adjust the machines and produce them again until the inspection is passed. Finally, our QC team records the critical sizes and results on the inspection logs.

02

Inprocess Quality Control Inspection

EOS has an Inprocess Quality Control (IQC) team that implements quality control tasks after the first article inspections. Sometimes machines have their machining tolerances as time passes by during the production, even if the sizes of the first articles are correct. So IQC team becomes very important to keep our precision steady. Our IQC team needs to check the quality of the after machining parts, after electroplating parts, pre-assemble parts, etc. An IQC report will be issued by our IQC team when they finish the inspection tasks.

03

Finished Products Inspection

EOS applies finished product inspection on every single lock cylinder that we manufacture. Thanks to the low machining tolerance, we may feel the rotating sense is tight when we finish assembling the lock cylinders. So our finished products inspection team also needs to implement the tasks of fixation and inspecting.

As to the master key system cylinders, our QC team needs to finish inspecting the mutual opening rate of the system and accessibility of the MK keys. They choose the cylinders with adjacent key numbers and test if the cylinders are mutually opened or not. This method can test the precision of the cylinder and judge whether the cylinder is qualified to make a master key system or not.

04

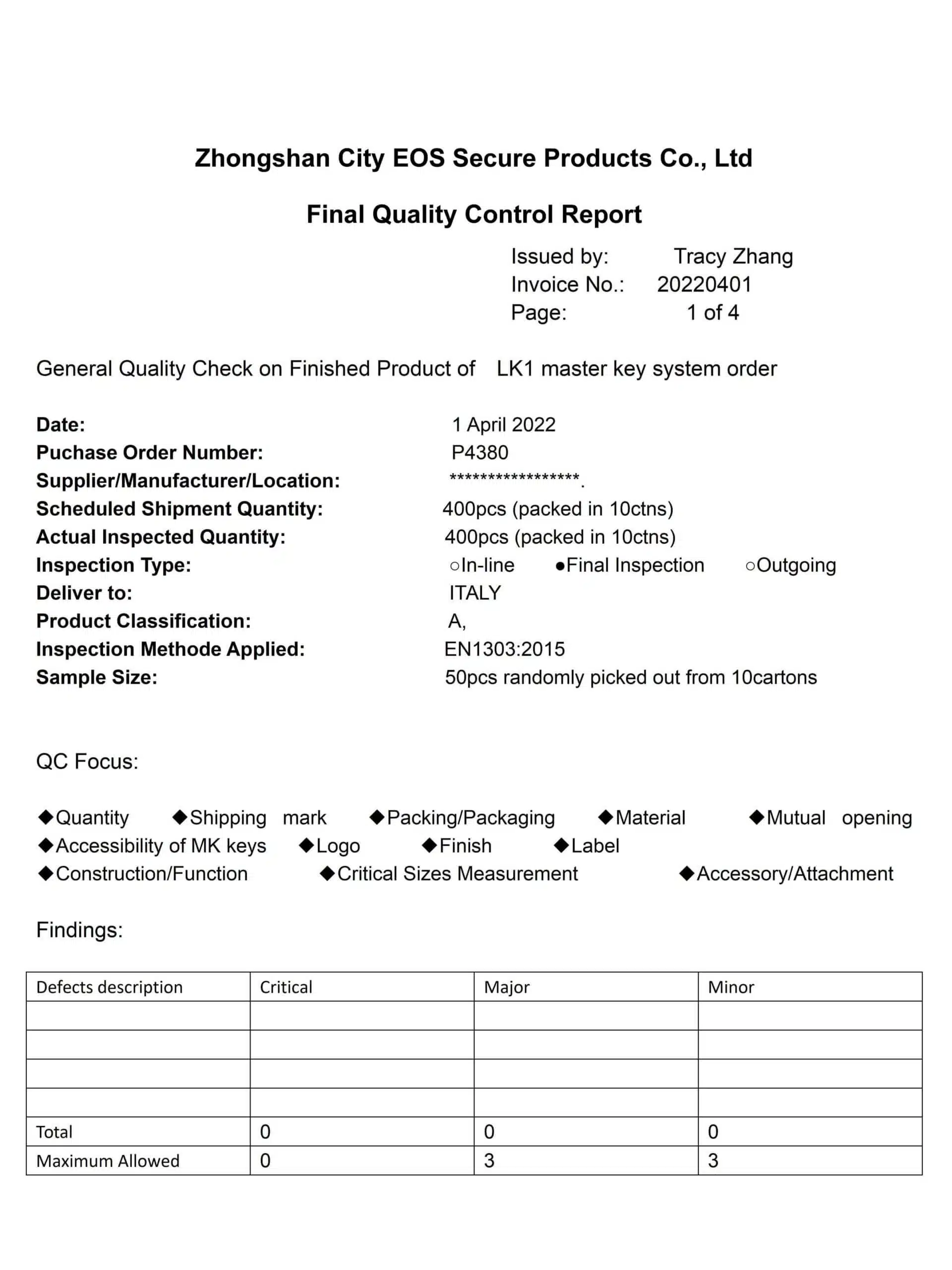

Final Quality Control Report

EOS understands that our customers are eager to have a report listing some pictures of their orders. So our customers can judge the quality by checking the information in the reports. EOS issues FQC (Final Quality Control Report) to our customers regarding every PO. In the FQC report, we will show the pictures of the shipping mark, product packing, logos, finishes, critical sizes measurement, etc. Before shipping the goods, our customers can have a clear look at the quality of their orders, and they feel assured of their requirements in the orders.

05

Testing Method And Standard

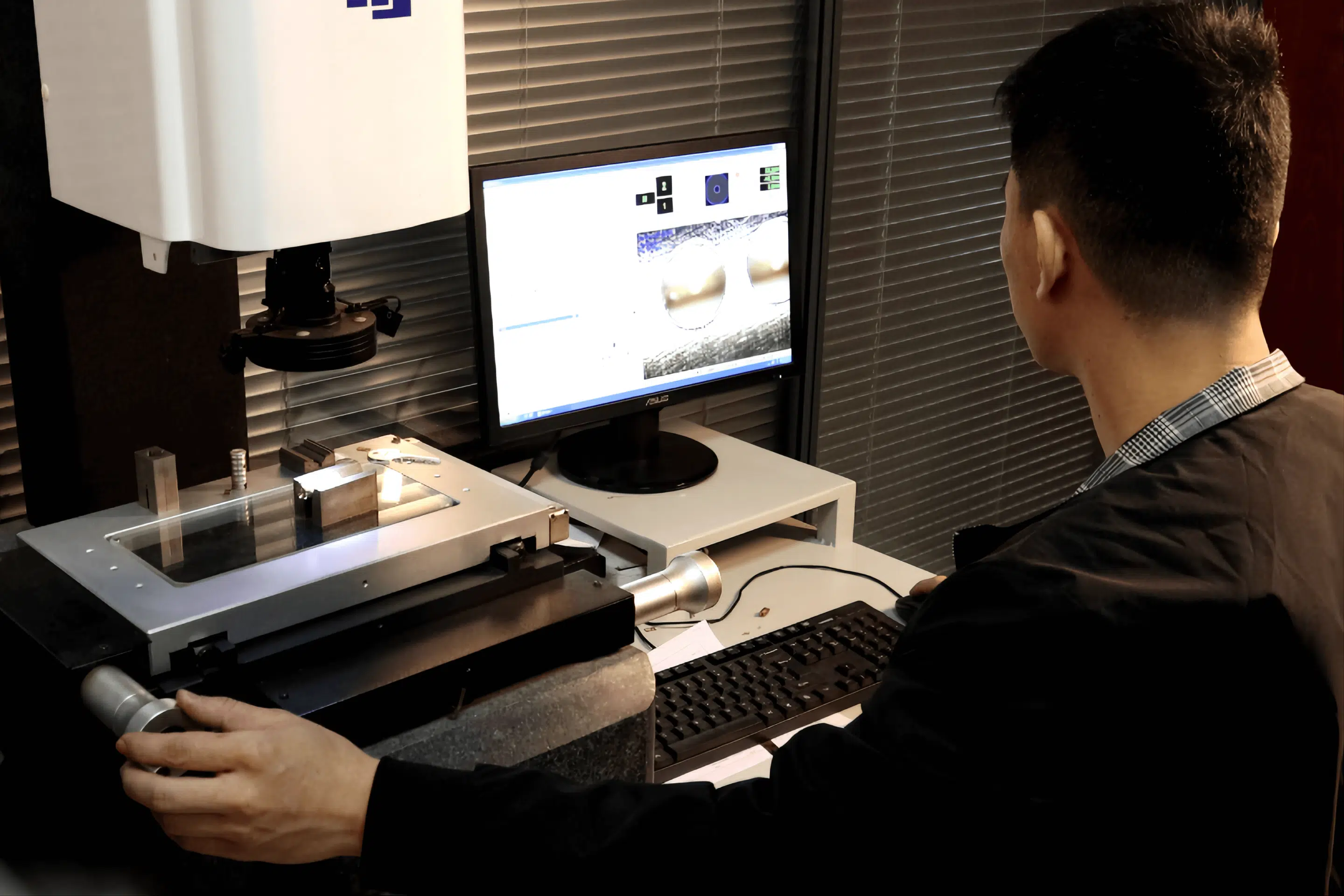

EOS strictly complies with the lock cylinder testing standard EN1303 and ANSI. EOS invested in cycle testing machines, anti-drilling testing machines, hardness test machines, salt-spray test machines, 2.5D measuring instrument machines, all kinds of gauges, etc., to improve the testing level and comprehensive product quality. Due to the deep understanding of the international testing standards, EOS thinks highly of the product cycle time, anti-drilling ability, key-related security, mutual opening, accessibility of MK keys, etc. We help our customers pass certifications like SKG***, EN1303 6D rating, etc.

How EOS Controls The Quality

Master key system cylinders and Security cylinders manufacturer

01

First Article Inspection

EOS invested in over 50 sets of CNC machines, which means our engineers only need to adjust the program in the computer, then finish the adjustment on the machines when producing different parts. After adjustment to the machines, our engineers and QC team will check the sizes and precisions of the first articles with clear work instructions and drawings. If the first articles fail to pass the inspection, our engineers re-adjust the machines and produce them again until the inspection is passed. Finally, our QC team records the critical sizes and results on the inspection logs.

02

Inprocess Quality Control Inspection

EOS has an Inprocess Quality Control (IQC) team that implements quality control tasks after the first article inspections. Sometimes machines have their machining tolerances as time passes by during the production, even if the sizes of the first articles are correct. So IQC team becomes very important to keep our precision steady. Our IQC team needs to check the quality of the after machining parts, after electroplating parts, pre-assemble parts, etc. An IQC report will be issued by our IQC team when they finish the inspection tasks.

03

Finished Products Inspection

EOS applies finished product inspection on every single lock cylinder that we manufacture. Thanks to the low machining tolerance, we may feel the rotating sense is tight when we finish assembling the lock cylinders. So our finished products inspection team also needs to implement the tasks of fixation and inspecting.

As to the master key system cylinders, our QC team needs to finish inspecting the mutual opening rate of the system and accessibility of the MK keys. They choose the cylinders with adjacent key numbers and test if the cylinders are mutually opened or not. This method can test the precision of the cylinder and judge whether the cylinder is qualified to make a master key system or not.

04

Final Quality Control Report

EOS understands that our customers are eager to have a report listing some pictures of their orders. So our customers can judge the quality by checking the information in the reports. EOS issues FQC (Final Quality Control Report) to our customers regarding every PO. In the FQC report, we will show the pictures of the shipping mark, product packing, logos, finishes, critical sizes measurement, etc. Before shipping the goods, our customers can have a clear look at the quality of their orders, and they feel assured of their requirements in the orders.

05

Testing Method And Standard

EOS strictly complies with the lock cylinder testing standard EN1303 and ANSI. EOS invested in cycle testing machines, anti-drilling testing machines, hardness test machines, salt-spray test machines, 2.5D measuring instrument machines, all kinds of gauges, etc., to improve the testing level and comprehensive product quality. Due to the deep understanding of the international testing standards, EOS thinks highly of the product cycle time, anti-drilling ability, key-related security, mutual opening, accessibility of MK keys, etc. We help our customers pass certifications like SKG***, EN1303 6D rating, etc.

eos security cylinder factory](https://www.eos-secure.com/wp-content/uploads/2022/05/MVI_129220220511-0841421.png.webp)

![MVI_8826[00_00_05][20220511-084158] eos lock cylinder quality control](https://www.eos-secure.com/wp-content/uploads/2022/05/MVI_882600_00_0520220511-084158.png.webp)

![MVI_8830[00_01_33][20220416-173223] 拷贝 eos lock cylinder electroplating](https://www.eos-secure.com/wp-content/uploads/2022/04/MVI_883000_01_3320220416-173223-拷贝.png.webp)